Off-line re-pelletising systems for thermo-plastic plastics

Our recycling extruders are optimised for the feeding of light, non-free flowing feed materials.

Our special screw geometry makes it possible to process even extremely light feed materials without pre-compaction or thermal pretreatment. As a result, there is no thermal and oxidative preloading of the feed material in our systems, e.g. by agglomerators or cutting compressors, which is noticeable in the achievable granulate quality.

Our pelletising extruders for non-free-flowing feed material are equipped as standard with a feed silo, which is normally mounted directly on the feed area of the extruder. The feeding of our extruders can be discontinuous and thus minimises the manpower requirement in the material feeding area. Our modular systems are optimally designed for the respective application.

Our product range includes standard systems with capacities from 50 kg/h to over 1,800 kg/h for all thermoplastics.

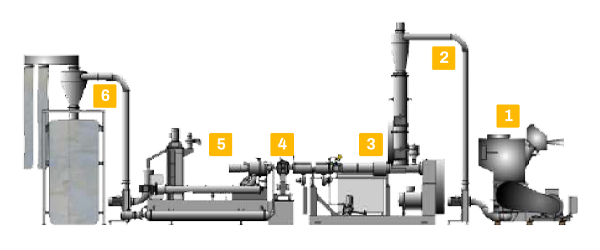

How it works

- Preliminary shredding, usually with a granulator.

- The already shredded input material is transported by fan into the extruder silo.

- A stirrer integrated in the silo ensures even feeding of the extruder regardless of the material type. The extruder is then fed with the shredded material.

- In the extruder, the heart of the plant, the material is then gently melted under hermetically sealed conditions and thus without oxidation.

- It is then transported to the next downstream screen changer and then on to the pelletising head where the melted material is processed to form pellets and then dried in a centrifuge.

- The pellets are transported by a fan into a big bag station, a silo or a container.

Area of application

- For thermo-plastic plastics

- Recycling of edge trim, drive rollers and waste produced by the plastic processing industry

- Designed for various input materials, e.g. film and non-woven, injection-moulded parts, profiles, tubes, drive lumps, milled goods, hollow objects, fibres, yarns, monofilaments and much more

- Also suitable for printed and coated materials

- Clean production waste and lightly soiled or damp materials can be processed just as easily

The recycling is carried out in a single process and results in first-class pellets that can be processed further in a range of different processes

Our supply range includes standard systems with material through-put performances from 30 kg/hour to more than 1,300 kg/hour

Feeding can be carried out using various methods: Manually by the plant operator, pneumatically via a feed pipe, via a conveyor belt, or fully-automated with a draw-in roller

The conical special screw enables processing of both heavy and light materials that do not flow freely. If necessary, the screw geometry can be matched to the raw materials

The screw design guarantees a gentle and homogenous melting of the plastic, without the need for precompaction or material damaging pre-treatment

The combination of hot and cold zones benefits the melting process and enables the setting of rheologically optimised melting temperature profiles

The robust, open construction of the Sikoplast plants not only ensures simple operation, but it also eases access and the maintenance of the system as well

Modularly constructed Sikoplast systems enable a flexible position and composition of the components desired by the client

At the request of the client our systems can be fitted with additional dosing stations to enable the addition of additives or master batches

The regeneration extruder is fitted as standard with a bunker silo mounted to the infeed area. This acts as a buffer and ensures constant material through-put

Thanks to the integration of melting filters, the material purity levels are increased and/or can be adapted as required to meet the current needs

When the materials are critical (damp; printed) the extruder is fitted with a degassing zone and a vacuum pump to extract the volatile components from the melted materials

Extruder systems offline

Our recycling extruders - optimised for the feeding of light, non-free-flowing feed materials.

To extruder systemsSikorex edge trim system

The SIKOREX series form the basis for an economic preparation - optimised for the return of roll material or for direct edge trim return.

To Sikorex edge trim systemHybrid edge trim system

The HYBRID system covers all requirements of a modern spunbond production - even on high-speed winders with speeds above 1,500 m/min a direct edge trim return is guaranteed.

To Hybrid edge trim systemWashing plants

Our washing system with friction washer and the patented wet separation stage with integrated pre-flotation enable above-average purity grades, even with heavily soiled feed material.

To washing plants