For 35 years, Jovipack has been recycling its production waste with a plant from Sikoplast - of course, the new regranulation plant is again from Sikoplast

The French market leader for air bubble films, JoviPack , began processing its production waste 35 years ago. The HKS 180/110 off-line regranulation system supplied by SIKOPLAST at the time still makes a valuable contribution to the production of high-quality granules today. Mickael Beautemps , R&D Manager at JoviPack , emphasizes the growing importance of plastic recycling for his company, which goes hand in hand with the recent decree from the French Ministry of the Environment for more sustainability: “Environmental protection is very important to us. We are working hard to reduce the volume of waste. In addition, French regulations and market demands are increasingly demanding to raise the percentage of recycled material in our products”.

JoviPack currently recycles around 300 metric tons of production waste 220 days a year. The regranulate then flows into production for the manufacture of new air bubble films. The recycling capacities at JoviPack are no longer sufficient. According to the management of JoviPack , the decision to buy a new, more powerful SIKOPLAST recycling machine was not particularly difficult: "Since we have a SIKOPLAST system from 1987 that is still running today, it was clear that these machines are very robust and reliable. That is the main reason why we chose SIKOPLAST again ".

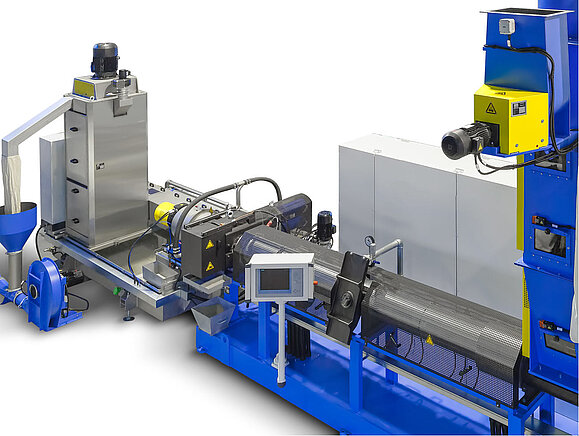

Since the new SIKOPLAST system will not only be able to process higher throughputs in the future, but also different polymers such as LD-PE, PE, PP film waste, the input materials were tested on the technical center at SIKOPLAST. The convincing results from the test run, the good service and the experience with the existing SIKOPLAST system left the decision-makers at Jovipack in no doubt about ordering a new system of the type HKS140/90 from SIKOPLAST: "All of this gave us a good idea of the equipment and made us more confident for the success of this project,” said Mr. Beautemps. This model will be exhibited at K-2022 at SIKOPLAST Recycling Technology-Hall 9 Stand A46.

Mr. Stylianos Nikolaou , Managing Director of SIKOPLAST Recycling Technology GmbH, thanks Jovipack for the many years of trusting cooperation and adds: "Quality and customer satisfaction are our top priority. The increased recycling rate will ensure regulatory compliance and promote a closed circular economy.”

(https://www.k-zeitung.de/nachweislich-zuverlaessige-regranulieranlage)