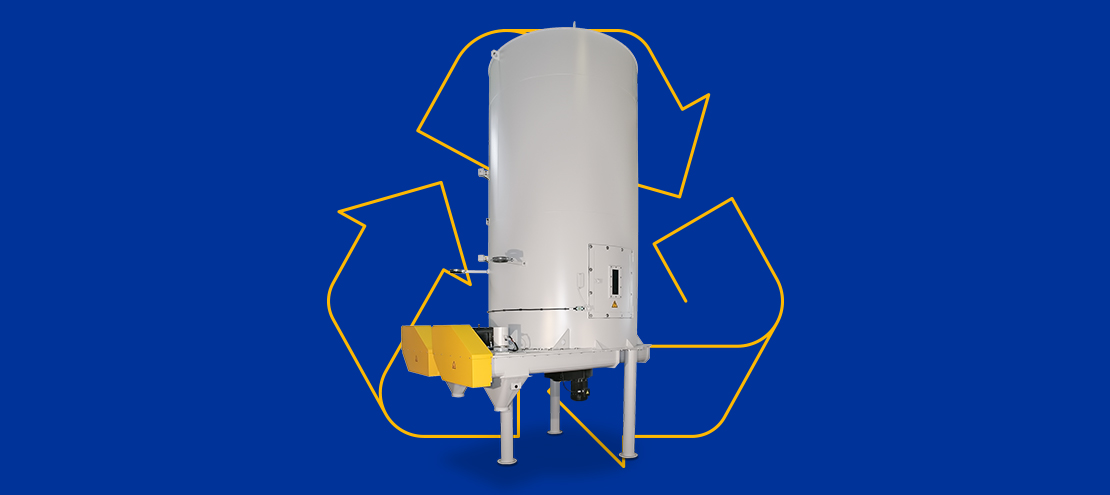

Silos

- for storage, mixing and discharge of the filling material.

- suitable especially for grinding material with low bulk density

- integrated mixing arm to avoid bridge formation

- homogeneous mixing of the feed material

- Material discharge by means of discharge screws embedded in the silo bottom (infinitely variable)

- prepared for pneumatic feeding

- 1 manhole incl. sight glass and limit switch

- welded construction in mild steel, primed and painted on the outside

- Maximum rotary wing level detector

- Discharge screw speed frequency controlled

Extruder systems offline

Our recycling extruders - optimised for the feeding of light, non-free-flowing feed materials.

To extruder systemsSikorex edge trim system

The SIKOREX series form the basis for an economic preparation - optimised for the return of roll material or for direct edge trim return.

To Sikorex edge trim systemHybrid edge trim system

The HYBRID system covers all requirements of a modern spunbond production - even on high-speed winders with speeds above 1,500 m/min a direct edge trim return is guaranteed.

To Hybrid edge trim systemWashing plants

Our washing system with friction washer and the patented wet separation stage with integrated pre-flotation enable above-average purity grades, even with heavily soiled feed material.

To washing plants