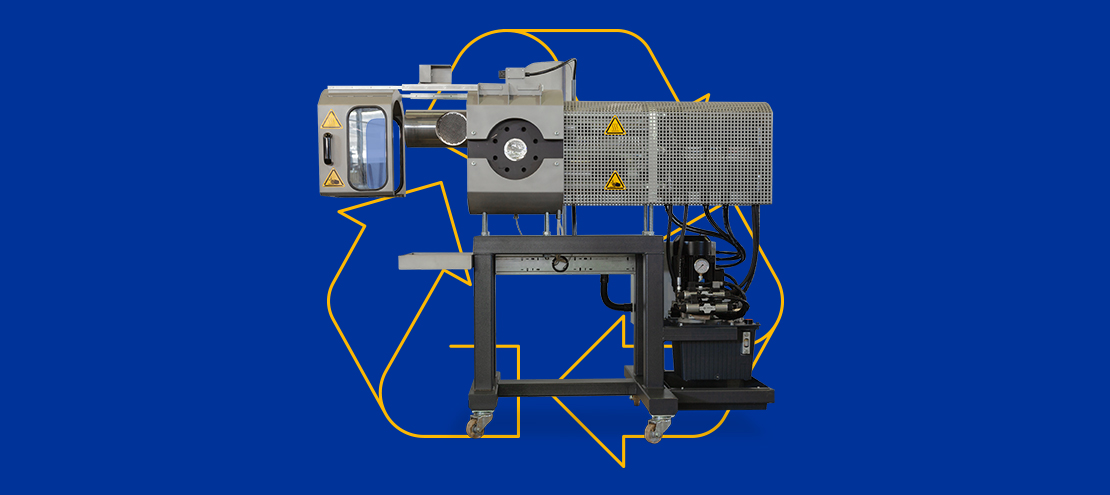

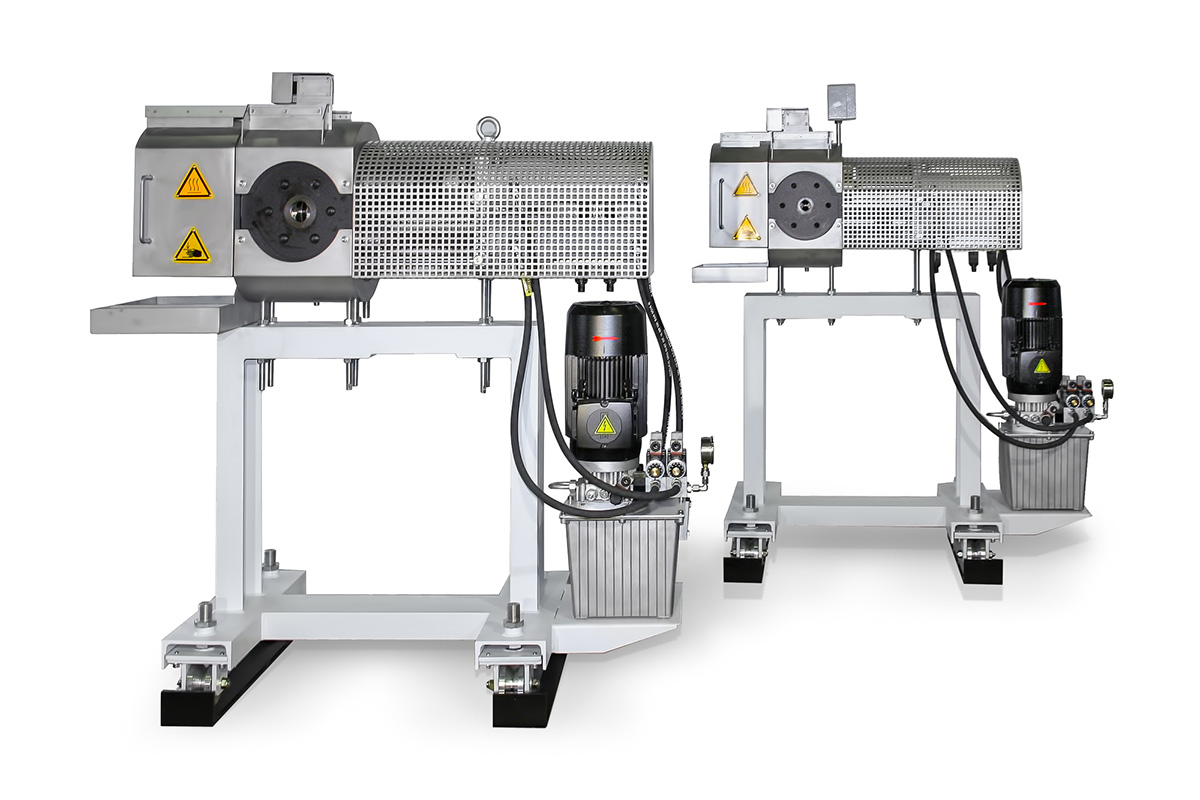

Screen Changers

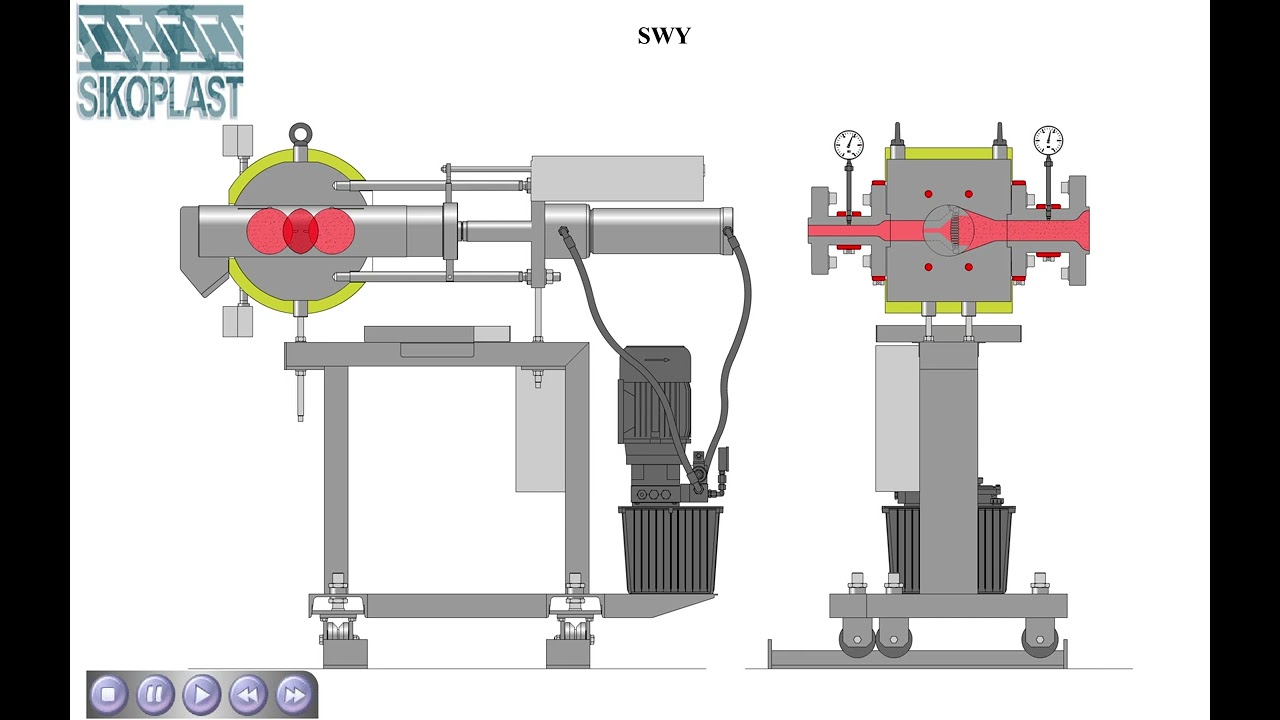

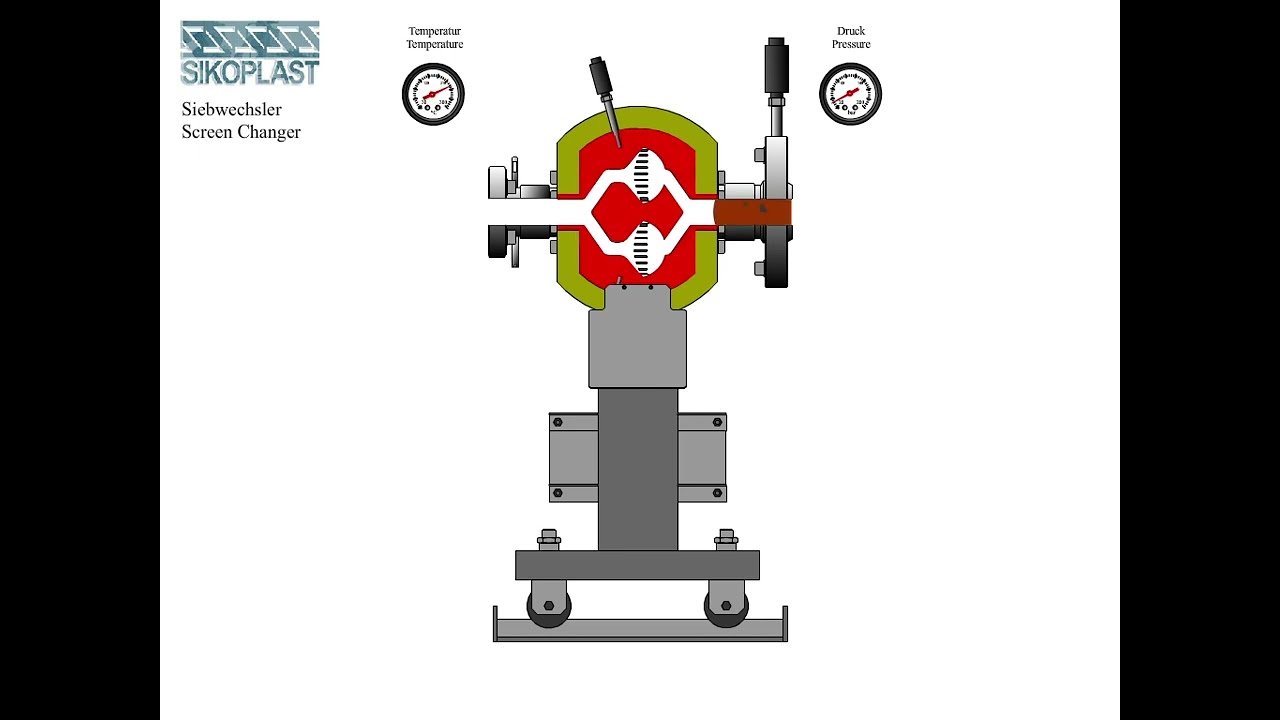

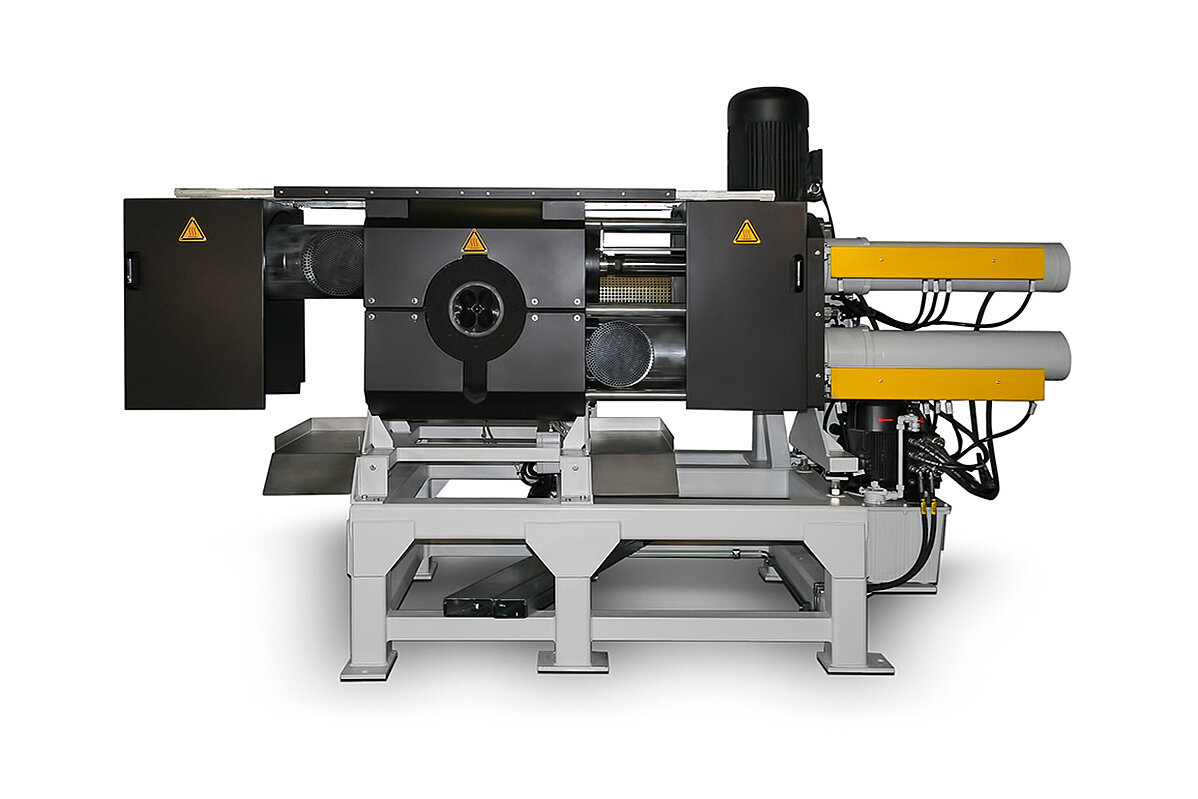

For the filtration of plastic melts we offer single and double piston screen changers. The screen diameters range from 58 mm to 250 mm. The screen changers are designed as continuous filters, so that a screen change can be carried out during operation without interrupting production. The pistons are moved hydraulically.

Depending on the equipment variant, the screen changers are supplied with position switch and visualisation.

The screen changers are designed in such a way that they can be integrated into any installation if required. Corresponding adapter flanges allow adaptation to all common extruders. Describe your task to us and we will be pleased to offer you the suitable melt filter.

Bilder

Available for material throughputs of up to 2.000 kg/h, screen diameters from 58 mm to 250 mm

Depending on your requirements and application, both 1-plunger and 2-plunger screen changers can be used

Continuous operation, no production interruptions, even during screen changes

The screen changer pistons are extended and retracted hydraulically

Low maintenance, simple operation, continuous pressure monitoring

Extruder systems offline

Our recycling extruders - optimised for the feeding of light, non-free-flowing feed materials.

To extruder systemsSikorex edge trim system

The SIKOREX series form the basis for an economic preparation - optimised for the return of roll material or for direct edge trim return.

To Sikorex edge trim systemHybrid edge trim system

The HYBRID system covers all requirements of a modern spunbond production - even on high-speed winders with speeds above 1,500 m/min a direct edge trim return is guaranteed.

To Hybrid edge trim systemWashing plants

Our washing system with friction washer and the patented wet separation stage with integrated pre-flotation enable above-average purity grades, even with heavily soiled feed material.

To washing plants